Welding Categories

Welding Categories  Arc Welding

Arc WeldingArc Welding

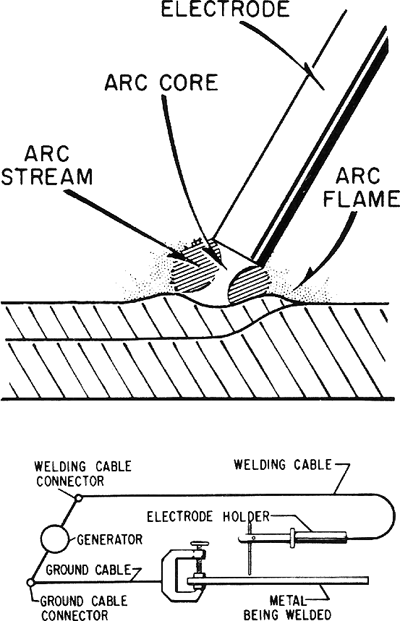

In arc welding a welding power supply is used to create an electric arc. The electric arc is created between the base metal that is to be welded and the electrode that is used. The electrode may be consumable or non consumable. What is means is that the electrode may be consumed in the process or not consumed based on the process that is used. When the electrode is consumed it is mostly to provide for the filler material that will help to make the weld or the joint between two metals. The power supply that is used can either be alternating current or direct current. Most of the times, the area of weld is protected by the use of a shielding gas or by the use of slag. This is done so that an atmospheric gas such as oxygen or nitrogen does not contaminate the area of weld.

The power supply that is used may be constant current or constant voltage. This means either the current or the voltage is constant from the power supply that is used. The voltage will be directly related to the length of the arc and the current is directly related to the heat that is generated. Therefore using these two parameters the welding can be controlled.

|

In the shielded metal arc welding process the electrode used is consumable. The electric current will strike an arc between the consumable electrode and the base metal that is being used. The consumable electrode is also known as a welding stick. The stick should be made of a material that is compatible with the base material. The electrode is often covered with a flux that gives off vapors when the welding operation is carried out. This vapor provides for the shield during the welding process by shielding the welding area to keep out atmospheric gasses like nitrogen and oxygen to contaminate or corrode the area. This will help to weld the two pieces together. This is the simplest of the processes available which requires very little technical training. However this process of welding is limited to welding ferrous materials only.

In a gas metal arc welding process, the welding wire that is fed will work both as the filler material as well as the electrode. This welding process will normally make use of the constant voltage direct current power source. However constant current alternating current can also be used for this process. This process is very prevalent in the automobile industry with the number of applications available in fabrication and repair.

|

On our website you will find a number of equipment related to arc welding. Therefore if you are looking to take up welding as a hobby then this is one of the best processes you can start with as this does not require any technical training. You can make sure that you have the best of the equipment available when you shop with us. Look through our website and you will find all the equipment that you need to get you started with welding.

The Arc welding is a process utilizing the concentrated heat of an electric arc welding to join metal by fusion of the parent metal and the addition of metal to the joint frequently provided by a consumable electrode.

The current arc welding source may be a rotating rectifier, generator or transformer and must have transient and static volt-ampere characteristics planned for arc welding stability and weld performance.

Electric current for the arc welding may be either direct or irregular, depending upon the material to be welding and the individuality of the electrode used.

| You want to buy a ARC Welder | |